Thin-Film Material Science and Processing

Thin films are important because they offer the potential for low-cost processing with minimal material usage while fulfilling application requirements. Importantly, this can enable cost-effective applications for expensive raw source materials. Thin films also can enable applications where low weight and mechanical flexibility are crucial.

Capabilities

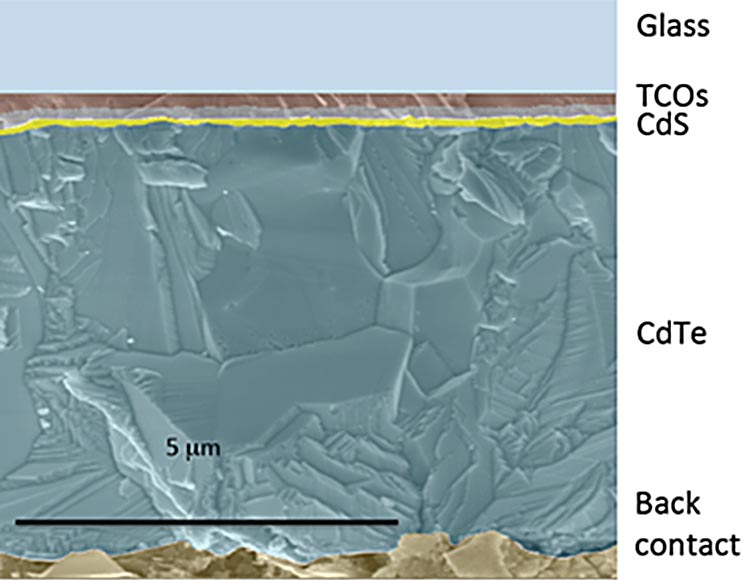

Cadmium Telluride PV

Our capabilities and expertise in cadmium telluride (CdTe) PV consist of polycrystalline films deposition and device processing including buffer layers, transparent conducting oxides and contact materials, epitaxial film growth and device processing, CdTe doping expertise, and deposition onto flexible substrates.

Contact

Matt Reese

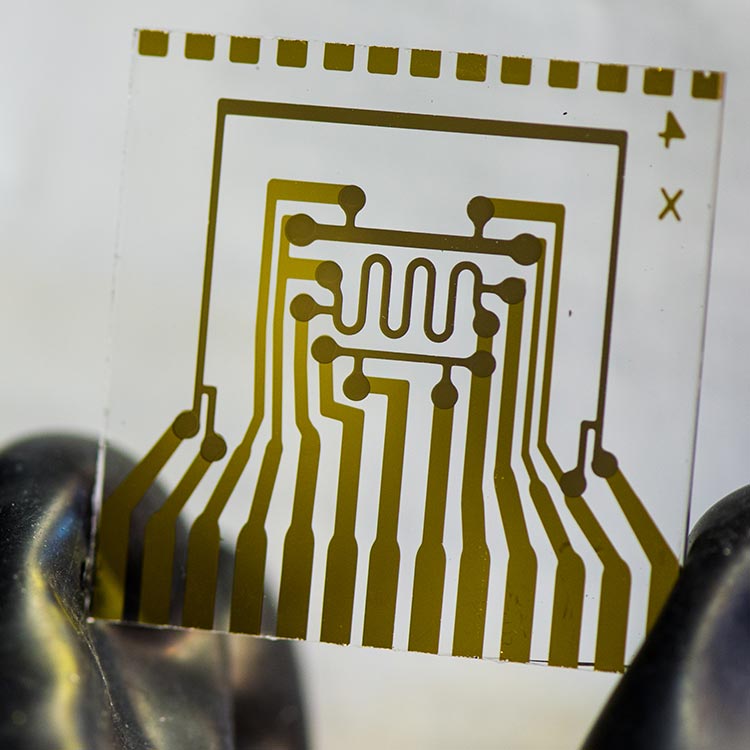

Copper Indium Gallium Selenide PV

Our capabilities and expertise in copper indium gallium selenide (CIGS) PV consist of polycrystalline films deposition and device processing including buffer layers, transparent conducting oxides and contact materials, deposition onto flexible lightweight substrates, and large-area (6"x6") deposition.

Contact

Lorelle Mansfield

Lorelle.Mansfield@nrel.gov

303-384-7884

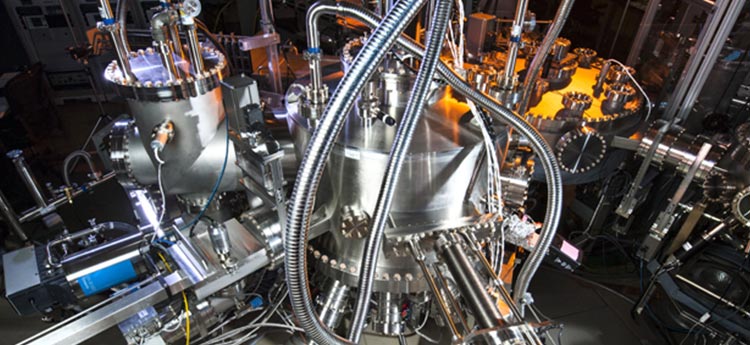

Atmospheric Processing Platform Capabilities

At the Process Development and Integration Laboratory, the Atmospheric Processing Platform (APP) offers powerful capabilities with integrated tools to deposit, process, and characterize PV materials and devices. Different methods are used to deposit ("write") materials onto a variety of substrates, which are then further processed using rapid thermal processing. What is unique about the APP is that these processes are performed at atmospheric pressure, without the requirement for expensive vacuum equipment.

Contact:

Rosemary Bramante

Vapor Barrier Diffusion Measurements

Barriers to oxygen and moisture are critical packaging components for a wide variety of industries. The requirements of each application vary significantly, with differing needs for cost and permeation rates. We have developed a quantitative high-throughput technique that can measure many barriers in parallel with unsurpassed sensitivity.

Contact:

Matthew Reese

Material Characterization with X-Rays

Our X-ray capabilities include X-ray diffraction (XRD) and X-ray fluorescence (XRF) characterization. Associated capabilities are a hot stage for XRD, mapping capabilities for XRD and XRF, and micro-XRF mapping.

Contact

Philip Parilla

Philip.Parilla@nrel.gov

303-384-6506

Contact

The Materials Science Center is part of the Materials, Chemical, and Computational Science directorate, led by Associate Lab Director Bill Tumas.

Share